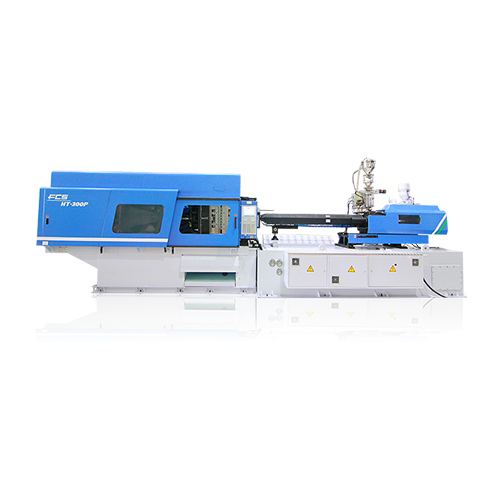

PET瓶胚射出机CM - 250

产品分类 : 卧式注塑机

专业研究/开发PET整厂设备配套工程。 PET专用特殊螺杆,高混练塑化成型。射出成型机全数位化,采用4个CPU电脑分工系统。原料除湿干燥机,采用世界标准(露点-40℃)。模具材质不锈钢热处理,寿命保证200万模次。热绕道、阀胶气门、温度控制系统,采用日本SEIKI。冷冻及空调采用双回路负压系统。提供瓶胚与吹拉成型技术咨询。

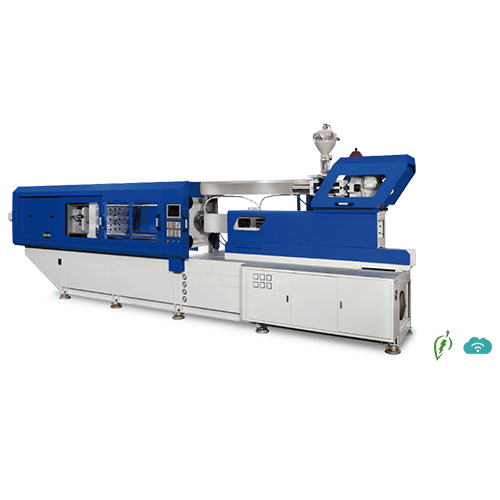

PET伺服节能注塑机伺服120PET伺服470PET

产品分类 : 卧式注塑机

Standard L/D ratio of 24 times and above for good plasticizing quality. Application of barrier type screw features and an extra barrier ridge to ensure homogenous plasticization when melting PET. Because of the viscosity of the PET, the screw speed and capacity of the hydraulic motor is upgraded to achieve higher plasticization. Compatible with auxiliaries such as PET preform molds, material dryer, mold sweat dehumidifier, water chiller, conveyor and post-cooling automation. Optional features such as a shut-off nozzle or an ejector on the fly are available. These are for shortening the total cycle time and maximizing the output.

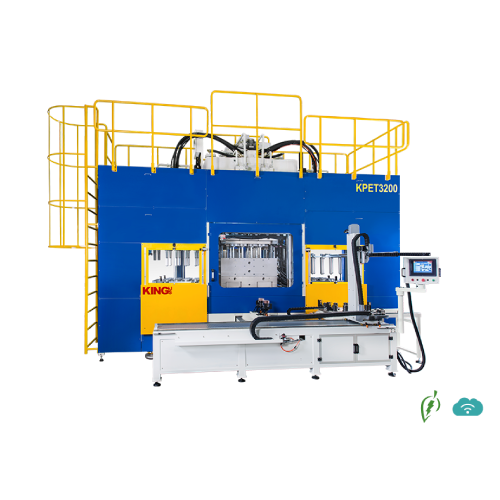

五加仑PET 瓶胚射出机

产品分类 : 卧式注塑机

KING’S SOLUTION CORP. acquired 18 years of 5-gallon PET preform production practice experience from KING'S MACHINERY ENGINEERING CORP. We provide the full process of Dehumidification Drying raw materials, quantitative additive color mixing machine, rapid and stable injection molding output of bottle preform, mold with 8+8 hot runners, rapid cooling robot mechanism, and the blowing bottle machine itself; Total production cost down with high productivity, and lowest blow bottle defect rate of only 0.5%.

PET Preform Injection Molding Machine with 8+8 Cavity Mold

产品分类 : 卧式注塑机

KING’S SOLUTION CORP. acquired 18 years of 5-gallon PET preform making machine practice experience from KING'S MACHINERY ENGINEERING CORP. We provide the full process of Dehumidification Drying raw materials, quantitative additive color mixing machine, rapid and stable injection molding output of bottle preform, mold with 8+8 hot runners, rapid cooling robot mechanism, and the blowing bottle machine itself; Total production cost down with high productivity, and lowest blow bottle defect rate of only 0.5%. Providing high quality 5-gallon PET Preform skill, we promise to implant production technology into the customer's factory. In response to industry 4.0, KING’S will go across and focus on Big Data capabilities to develop production analytics data open to customers in the near future to form the unmanned factory.